A Chinese technology company, Safmax, has unveiled a revolutionary nano-membrane fabric capable of withstanding extreme temperatures up to 2,192°F (1,200°C) without melting, deforming, or losing strength. The innovation, showcased at the China Public Security Tech Expo, is being hailed as one of the most advanced fireproof and safety materials ever developed.

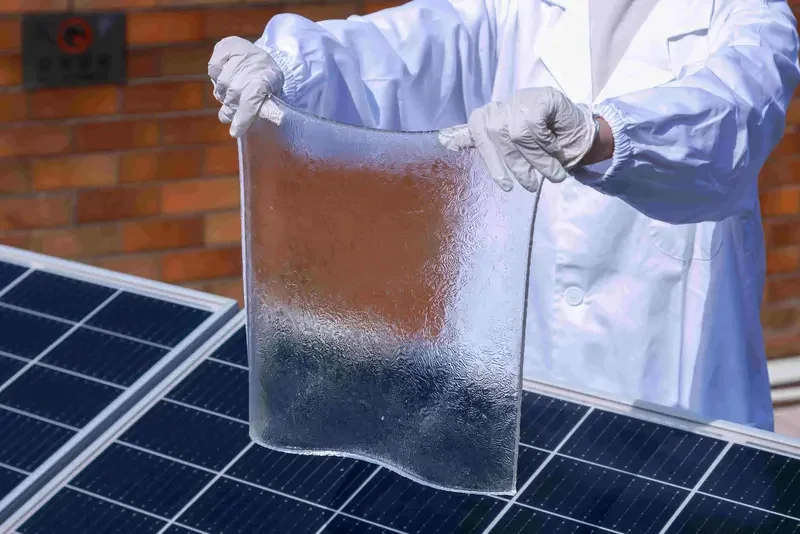

According to Safmax engineers, this cutting-edge material is fireproof, waterproof, windproof, and breathable, combining multiple layers of protection into a single, lightweight fabric. Unlike traditional flame-retardant suits that rely on bulky, chemically treated layers, this new nano-membrane technology provides the same—if not superior—heat resistance while remaining soft, thin, and flexible. The fibers used in the material are just one percent the width of human hair, making the fabric exceptionally light yet remarkably durable.

Safmax’s Chief Technology Officer, Jiang Huangsen, described the breakthrough as “a next-generation shield against fire hazards,” emphasizing its potential to transform firefighting gear, emergency blankets, and electric vehicle battery protection systems. He explained that the fabric could also prevent the spread of fires by isolating oxygen during incidents like battery explosions, a growing concern in modern electric vehicles.

During a live demonstration at the Expo, Safmax showcased the fabric’s unique properties—water could not penetrate the material, yet air could pass through easily, proving its waterproof, windproof, and breathable design. Engineers noted that this combination of protection and comfort makes it ideal for emergency response uniforms and industrial safety gear.

Experts believe the fabric’s effectiveness lies in its nanotechnology-based structure, which forms a thin but resilient protective layer. While Safmax has not disclosed the exact chemical composition, it reportedly avoids conventional flame-retardant compounds such as phytic acid, ammonium polyphosphate, or diphenylphosphine, instead relying on an advanced nano-coating process that provides superior heat resistance and flexibility.

Currently, most firefighter suits are made of Nomex and Kevlar, which, while strong and heat-resistant, tend to be heavy and restrictive due to multiple protective layers. Safmax’s nano-membrane material, by contrast, delivers equivalent safety in a much thinner form, enhancing mobility and comfort for firefighters and emergency workers.

Beyond firefighting, Safmax envisions broader applications in industrial plants, refineries, aerospace, military, and energy sectors, where high-temperature environments demand both protection and agility. By merging nanotechnology with advanced textile design, Safmax’s innovation could mark a turning point in how protective clothing is made—ushering in a new era of lightweight, multifunctional, and high-performance safety fabrics.